The data from 2022 indicates that the quantity of electric bicycles (e-Bikes) in China surged to 350 million, with an annual production exceeding 35 million, solidifying its position as the global leader in both ownership and manufacturing. Despite the widespread popularity of electric bicycles due to their convenience, recent statistics released by Shenzhen in 2019 reveal a sobering fact: fatalities resulting from electric bicycle accidents accounted for 40.98% of all road traffic fatalities.

Over the past five years, China has witnessed 830,000 eBike-related traffic accidents, primarily stemming from traffic rule violations, failure to use helmets, hit-and-runs, illegal entry into motorist lanes, running red lights, and other infractions. These incidents resulted in 18,000 fatalities and 186,000 injuries, with both the accident rate and death toll increasing annually. In response to this concerning trend, the Chinese Ministry of Public Security's Traffic Management Bureau has opted to introduce digital identity for e-Bikes and issue the ePlates in select pilot cities within Guangdong Province, aiming to mitigate and prevent further accidents.

These ePlates come in three distinct varieties: new national standard plates for civilian vehicles, new national standard plates for civilian industry use, and transitional identification for e-Bikes not meeting the new national standard, each distinguished by unique colors.

EMPTECH has played a pivotal role in this transition, delivering 12 million ePlates to 8 cities and regions across China. Especially, EMPTECH’s e-Bike Management Solution made its groundbreaking debut in Shenzhen in 2019, marking the city as the national pioneer in adopting this innovative technology.

EMPTECH has played a pivotal role in this transition, delivering 12 million ePlates to 8 cities and regions across China. Especially, EMPTECH’s e-Bike Management Solution made its groundbreaking debut in Shenzhen in 2019, marking the city as the national pioneer in adopting this innovative technology.

Shenzhen Pioneers Intelligent e-Bike Management

EMPTECH has been awarded the contract to deliver a comprehensive e-Bike management system to Shenzhen. The city’s groundbreaking initiatives in electric bicycle ePlate issuance not only addressed concerns about traffic accidents but also played a pivotal role in enhancing urban traffic management.

Nationwide Adoption

Since June 2021, the Chinese Ministry of Public Security's Traffic Management Bureau has spearheaded efforts to encourage cities nationwide to emulate the successes of trailblazing cities like Shanghai, Hangzhou, and Shenzhen by embracing the adoption of new ePlates with embedded electronic tags. This initiative streamlines monitoring, identification, and information access using mobile devices, allowing for vehicle recognizing, tracing and collecting evidence for traffic violations without being on-site.

EMPTECH’s Cutting-Edge ePlate Production & Personalization System

EMPTECH has successfully introduced ePlate Production & Personalization System. This system is the first of its kind domestically and has been honored with the Innovation Product Award from the Ministry of Public Security.

RFID electronic tags are embedded in ePlates, utilizing high-strength materials as the plate substrate to protect the RFID tags. The ePlate printing employs high-performance ink that's fade-resistant and aging-resistant, meeting the requirements for long-term use. By leveraging RFID chips, data collection or writing can be achieved seamlessly. This long-range recognition passive RFID ePlate ensures the principle of "1 Bike, 1 Identity".

EMPTECH's ePlate Production & Personalization System stands out for its automatic plate production, backed by precise AI visual detection before personalization. It utilizes state-of-the-art UV DoD printing technology and encoding for top-notch results.

The ePlate automated Production & Personalization Equipment EMP6822 boasts a production speed of up to 800 plates per hour.

EMP6822

Key Features:

• Contactless chip data encoding, OCR positioning, precise recognition

• 3D printing, glossy anti-counterfeiting, supports dual-color printing

• Multiple layer quality check on printing quality and accuracy, and automatic removal of defective plates

• Modular design, easy for maintenance

After personalization, it seamlessly conducts quality checks on both printing and chip information. Defective ePlates are swiftly removed, and the finished products are efficiently collected.

EMPTECH’s ePlate Semi-Finished Product Quality Inspection System

EMP8611

The fully automated ePlate semi-finished Product Quality Inspection equipment, EMP8611, checks the flatness of semi-finished plates and records their TID numbers for the next stage of production. This equipment can inspect up to 1200 plates per hour.

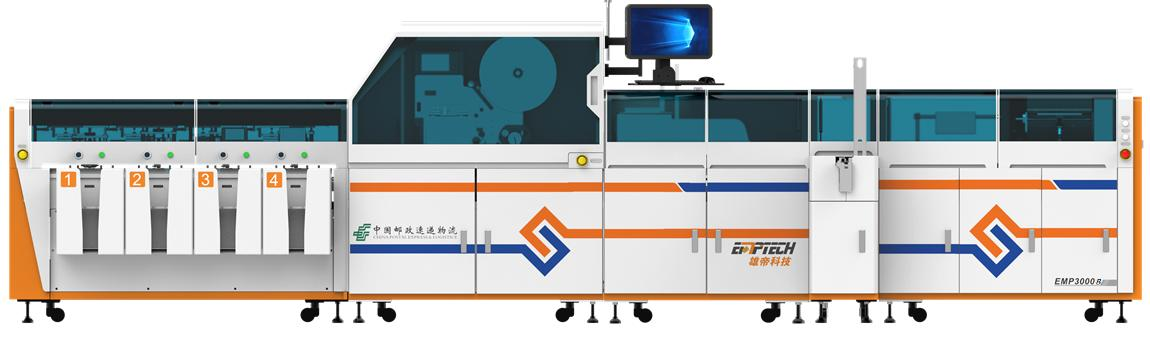

EMPTECH’s Advanced ePlate Sorting and Mailing Equipment

EMPTECH's ePlate Sorting and Mailing Equipment features envelope mailing, open sealing code printing, ePlate sealing, spray adhesive sealing, label printing and pasting, ePlate information verification, and automatic sorting functions. The envelope sorting and mailing speed is up to 1000 envelopes per hour.

EMPTECH’s Intelligent Production Monitoring System

The Central Production Monitoring System employs high-precision laser navigation and visual recognition technology to facilitate data exchange among robots, AGV transport vehicles, quality inspection, ePlate production, and Sorting and Mailing equipment through the scheduling system. By integrating and analyzing data efficiently and visually, it assists officers in identifying and diagnosing issues during the production process. This ensures robots perform designated tasks safely, orderly, and efficiently.

In conclusion, EMPTECH's comprehensive e-Bike Management Solution has demonstrated remarkable progress since its inception. Securing bids in key regions such as Shenzhen, Guangzhou, Fujian, Jiangxi, Nanning, Shijiazhuang, Xingtai, Shanghai, Zhejiang, and Daqing, spanning 8 cities and regions, underscores its widespread adoption and success.

Illustrating the effectiveness of the solution, the implementation of ePlates in Shenzhen has resulted in notable improvements and reductions, encapsulated by "three advancements and two declines". Data reveals significant enhancements in helmet-wearing compliance and overall regulatory adherence. Notably, the helmet-wearing rate surged from 64.9% in September 2020 to 76.7% in December 2020, reflecting an impressive 11.8% increase. Similarly, regulatory compliance rose from 62.2% to 80.0% during the same period, marking a substantial 17.8% improvement.

Beyond Shenzhen, the positive impact extends across the six districts beyond the original special economic zone, with significant reductions in e-Bike traffic accidents and theft cases, dropping by 5.9% and 34.0%, respectively. These compelling outcomes underscore the tangible benefits and effectiveness of EMPTECH's e-Bike Management Solution in enhancing safety, compliance, and overall urban mobility across various regions in China.